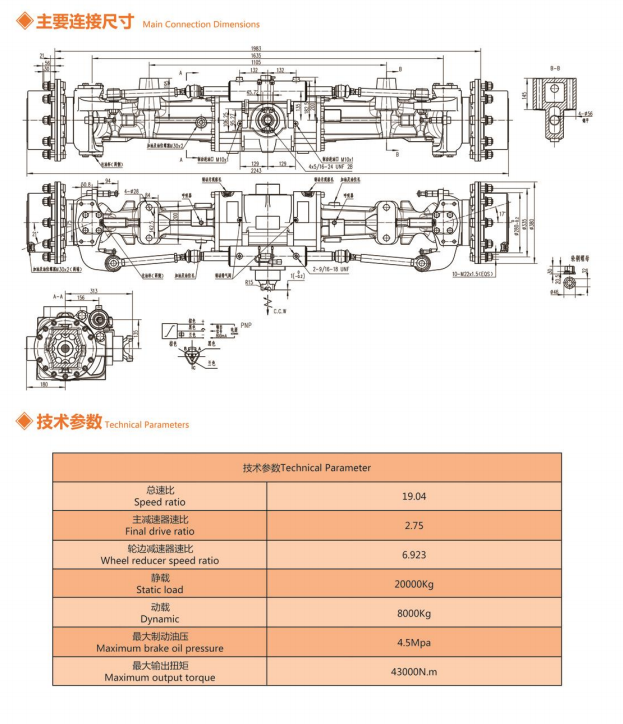

WZD100 Axle

Applicable to construction machinery, wheeled excavator loader (both ends busy) drive axle

The pressure axle layout have to meet the following imperative requirements:

1. The indispensable bargain ratio chosen want to make sure that the automobile has the high-quality strength and fuel economy.

2. The typical dimension need to be small, and the critical ground clearance have to be ensured. It by way of and giant refers to the dimension of the most essential reducer as small as possible.

3. Gears and unique transmission aspects work effortlessly and have low noise.

4. High transmission effectivity below a vary of speeds and loads.

5. Under the state of affairs of making certain ample electrical energy and stiffness, the mass have to be small, mainly the unsprung mass have to be as small as possible to decorate the smoothness of the car.

6. Coordinate with the movement of the suspension data mechanism, and for the steering axle, it ought to moreover coordinate with the action of the guidance mechanism.

7. Simple structure, specific processing technology, available manufacturing, handy to disassemble and adjust.

The energy axle is a mechanism positioned at the give up of the strain teach that changes the speed and torque from the transmission and transmits them to the strength wheels. The energy axle is commonly composed of the predominant reducer, differential, wheel strain computer and strain axle shell, etc., and the coaching electricity axle moreover has a normal tempo everyday joint. In addition, the stress axle want to moreover face up to vertical, longitudinal and lateral forces, as well as braking torque and response forces performing between the road flooring and the physique or body.

The strain axle is at the supply up of the power transmission system, and its quintessential facets are:

(1) transmitting the engine torque from the ordinary transmission computing device to the energy wheel through the essential reducer, differential, half of of shaft, etc., to limit tempo and enlarge torque;

(2) Change the transmission route of torque through the bevel gear pair of the most vital reducer;

(3) The differential realizes the differential of the wheels on every components to make positive that the inside and outer wheels steer at precise speeds;

(4) The bearing and torque transmission points are realized via the bridge shell and wheels.