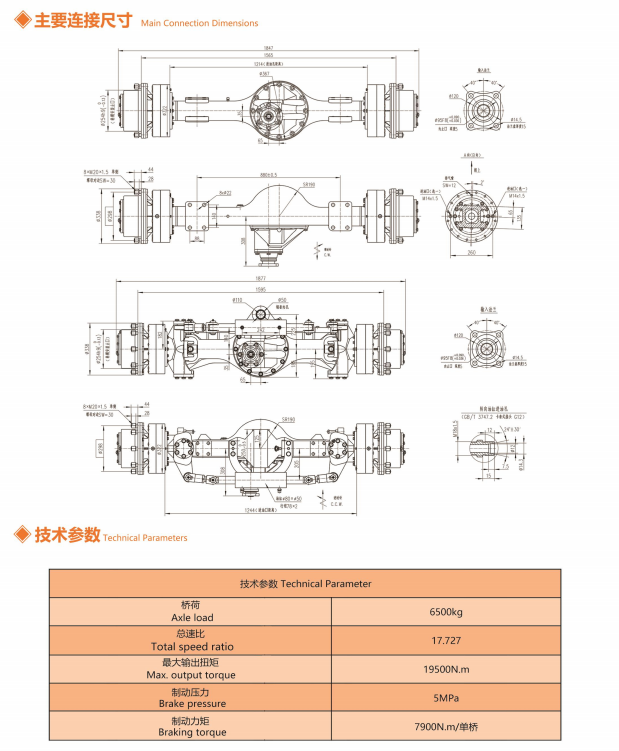

WL86 Axle

Suitable for construction machsinery, wheeled excavator loader

High transmission efficiency and low noise.

Optimized compact structure design.

The shaft housing has excellent rigidity and load capacity.

Large braking torque, stable and reliable performance.

Consistent quality and reliability

The drive axle is a mechanism located at the end of the drive train that changes the speed and torque from the transmission and transmits them to the drive wheels. The drive axle is generally composed of the main reducer, differential, wheel drive device and drive axle shell, etc., and the steering drive axle also has a constant velocity universal joint. In addition, the drive axle must also withstand vertical, longitudinal and lateral forces, as well as braking torque and reaction forces acting between the road surface and the frame or body.

The drive axle is at the end of the power transmission system, and its basic functions are: (1) transmitting the engine torque from the universal transmission device to the drive wheel through the main reducer, differential, half shaft, etc., to reduce speed and increase torque; (2) Change the transmission direction of torque through the bevel gear pair of the main reducer; (3) The differential realizes the differential of the wheels on both sides to ensure that the inner and outer wheels steer at different speeds; (4) The bearing and torque transmission functions are realized through the bridge shell and wheels.

The drive axle design should meet the following basic requirements:

1. The main reduction ratio selected should ensure that the car has the best power and fuel economy.

2. The overall dimension should be small, and the necessary ground clearance should be ensured. It mainly refers to the size of the main reducer as small as possible.

3. Gears and other transmission parts work smoothly and have low noise.

4. High transmission efficiency under various speeds and loads.

5. Under the condition of ensuring sufficient strength and stiffness, the mass should be small, especially the unsprung mass should be as small as possible to improve the smoothness of the car.

6. Coordinate with the movement of the suspension guide mechanism, and for the steering axle, it should also coordinate with the movement of the steering mechanism.

7. Simple structure, good processing technology, easy manufacturing, easy to disassemble and adjust.